Drought. It doesn’t just impact the quantity of your supply. Drought seriously impacts the quality of your water source, creating issues that directly impact your productivity.

When the reservoirs and rivers, your vital source waters, drop to below normal ranges, and stay low, it isn’t just the gallons that change. Low levels change the quality of the water, raising the solids and organic loading by limiting the zone from which you can draw water. The clearer zones of a full reservoir are simply not available.

Low source water levels mean shorter filter runs and reduced productivity

All that organic laden silt quickly fills up the media voids, reducing filter runs and requiring more frequent backwashing, slamming your productivity. Worse, even after backwashing, they leave behind organic and inorganic deposits, a biofilm that coats the media, further reducing void space and filter capacity.

These deposits build up on the media, filling the voids and increasing the effective media size. Often accumulating unevenly, the deposits reduce the uniformity of media particles. Perhaps worst of all, these deposits smooth out the angularity of the particles, preventing the full development of turbulent flow needed for optimum filter performance. The net result is further reduction in filter capacity and drastically reduced filtration effectiveness, creating channeling and short-circuiting, degrading the quality of your finished water.

Pressure drops increase and remain higher than normal even after backwashing. Energy costs rise while finished water production declines. And energy and production aren’t the only casualties of the drought – perhaps most important, finished water quality begins to deteriorate.

Processing less water but facing media replacement

In “normal times” you might look at the degradation of the media and decide it was time for media replacement. However, it hasn’t been that long ago that the media was new. It really shouldn’t need to be replaced.

The good news is, it doesn’t!

Blue Earth Products can show you how you can quickly and effectively dissolve these deposits, rinsing them away and restoring the media to like new condition.

Our chemist and engineers have thoroughly studied the chemistry of the filter restoration, understanding the impacts of media type, filter construction, and deposit composition. Our complete suite of patent pending products, combined with our expertise, will guide you through the selection and implementation process to full filter restoration.

Time efficient and thorough – in as little as 24 hours

Blue Earth Lab products don’t just work on the media. They penetrate all the way down through the underdrains, dissolving, cleaning, and restoring from the underdrains up. In as little as 24 hours:

- Filter media size, uniformity and angularity – restored

- Void space – restored

- Underdrain distribution efficiency – restored

- Filtration capacity – restored

- Run time – restored

- Pressure drop – reduced

- Backwash – reduced

- Energy costs – reduced

- Finished water quality – restored

- Productivity – restored

Restore productivity and improve finished water quality while saving money and time

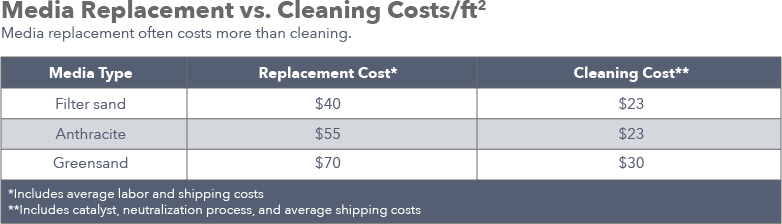

Media replacement is expensive AND time consuming, frequently taking 5 to 10 days, causing major disruption and increased hassle on your already taxed operations staff.

Cleaning media generally costs a fraction of the cost for media replacement – typically 30% to 50%. More important, because it can take as little as 24 hours, the disruption on your operations is drastically reduced and with minimal additional stress on your staff.

Custom tailored for you – our chemists and engineers work with you on YOUR media, YOUR deposits, YOUR system

With a core sample of your media, our experts will run bench tests to determine the right product, the right dosage and the right procedure to restore your filters to full, like new, capacity. We can assist you in developing a sequencing and remediation plan that will improve your operations in the shortest possible time and with the least disruption.

You can’t control the drought, but you can control your enhance productivity and water quality

During drought, it is even more important that you make every drop count – not only maintaining your productivity but keeping water quality high. You may not be able to recover the productivity lost to the increased solids loading. But don’t you owe it to your customers to reclaim the productivity lost from media degradation while protecting finished water quality? Don’t you owe it to your utility?

Let our dedicated technical team show you how you can restore your productivity, enhance water quality and take back control. Economically, efficiently, quickly.