Tanks are a major contributor to disinfection demand due to low turnover and long storage time. Dissolved solids accumulate and drop out of solution, and biofilms form from the organic matter that was not removed from the raw water. These accumulated sediments and biofilms also contribute to the formation of disinfection by-products regulated under the EPA Stage 2 rules. If left unchecked, these deposits can cause under-deposit corrosion, concrete spalling and other costly infrastructure issues. Therefore, proper tank cleanings should be performed on a yearly basis. There are several tank cleaning services available, here is an overview of the most common options.

- Pressure washing is the predominant method used by many utilities to clean and inspect tanks. Pressure washing can be effective in cleaning surface contaminates and biofilms, but cannot remove scale or the attachment points for new biofilms. The cost to pressure wash is comparable to the cost of chemically cleaning tanks; however, pressure washing delivers significantly lower quality results. Biofilm and scale growth will reappear and chlorine demand will increase shortly after cleaning.

- Diving is a popular inspection technique that allows a utility to inspect without removing the tank from service. Services that specialize in this inspection method require significant training and certification, in addition to specialized gear. Inspection costs range from $2,500 and $5,000 depending on tank size. Cleaning is additional based on the amount of silt in the tank. Divers attempt to scrub away biofilms on tank walls, but usually cannot remove scale or calcium buildups.

- Remote operated vehicles (ROVs) are similar to divers and produce the same low quality results. Costs can range from $22,000 to $26,000 per tank.

- Sandblasting and resurfacing a tank is a last alternative in cases where corrosion forces a tank to be repaired. This process costs approximately $250 to $290 per square foot and requires high level certified tank contractors. This process is time consuming and labor intensive.

- Chemical cleaning is a cost-effective option that produces long lasting results and full removal of biolfim, scale and attachment points for new biofilm growth. Utilizing a simple spray-on/rinse-off process, chemical cleaning is just as easy as pressure washing, but provides superior results. Cleaning can typically be completed in a day’s work and the chemicals are safe for most all tank surfaces. Depending on size and location of the tanks, cleaning can be completed for $5,000 to $20,000. Lower surface-borne chlorine demand, better tank inspections and delayed re-formation of deposits are all benefits to chemical cleaning.

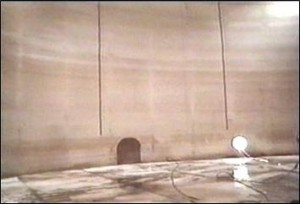

This image shows a water storage tank after pressure washing. Notice the stains and water lines are still visible.

This is the same tank after being chemically cleaned. All surface deposits and stains are removed.