Accumulated deposits on filter media contributes to declining run times, mixing of media, high head pressures, uneven backwashes, mud balls, media growth, media loss, cementing, channeling and other problems – all of which affect the performance, effectiveness and capacity of a filter.

STANDARD FILTER MEDIA ANALYSIS

If you are experiencing these problems, let Blue Earth Products perform a comprehensive chemical, physical and microscopic analysis of your filter media before you replace it. Once we determine the type of deposit and extent of surface deposition, we will determine the right filter media cleaning product for your treatment. The information provided by our analysis includes:

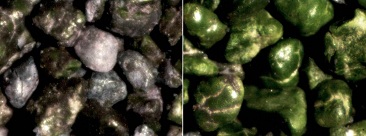

- Before and after visual and physical inspection

- Before and after microscopic pictographs

- Dry weight loss

- Calcium and magnesium removal

- Inductively Coupled Plasma (ICP) metals analysis

FILTER MEDIA CLEANING PROCESS

Blue Earth Products unique filter media cleaning process is a practical and cost-effective alternative to filter media replacement. Our products, Media Master® and Media Master® RR, clean and remove deposits to restore the performance of the media. Our filter media cleaning process is done in place, without disturbing the filter media in the filter bed. Media Master and Media Master RR penetrate the depth of the bed to the underdrains and effectively remove organic and inorganic deposits including algae, biofilms, iron, manganese and calcium scale. Media Master and Media Master RR work on a wide range of media types including anthracite, sand, greensand, ceramic media, GAC and other specialty media types. This process is effective for both gravity- and pressure-type filter vessels and can be finalized in 24 to 48 hours.

Contact us today to learn more about our filter media cleaning process.